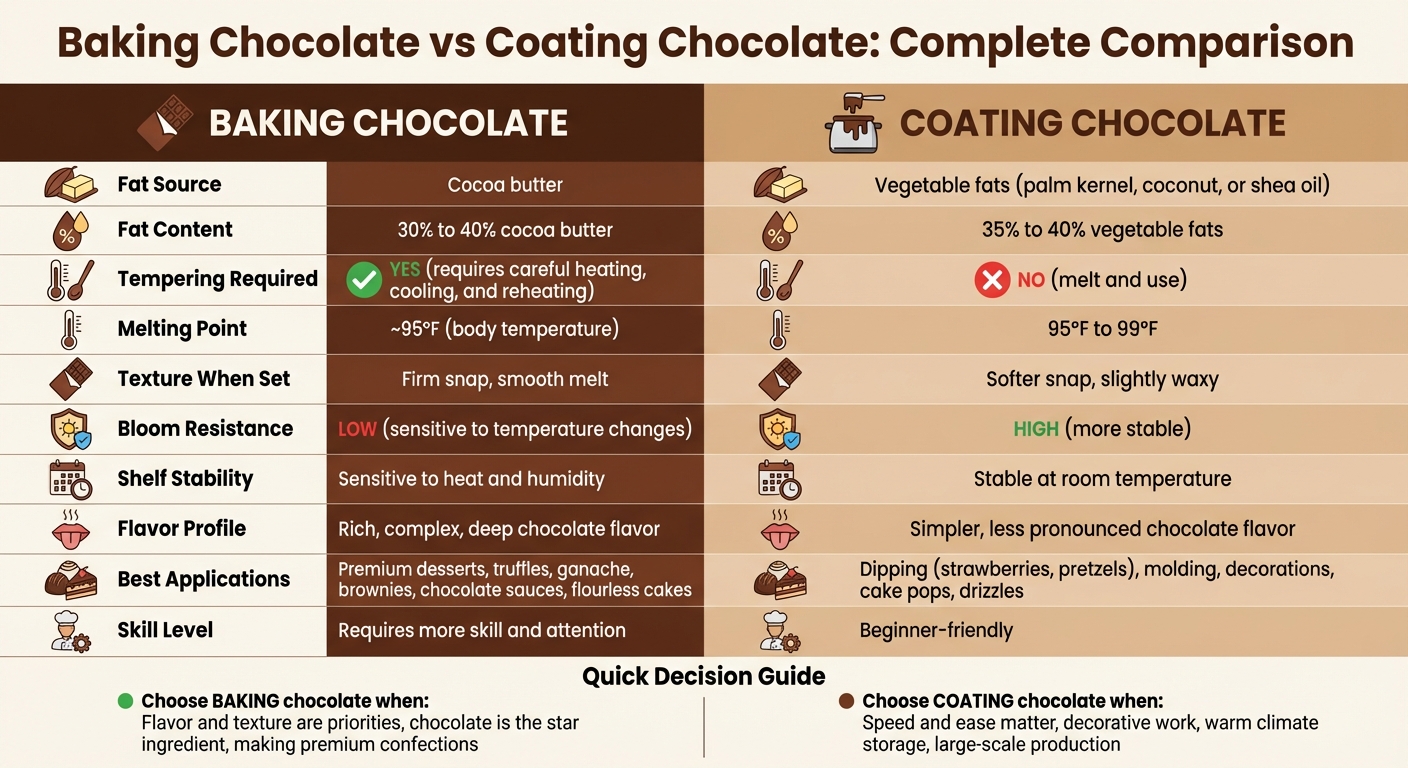

Baking chocolate and coating chocolate may look alike, but they serve very different purposes in the kitchen. Here's a quick breakdown:

- Baking Chocolate: Made with cocoa butter, it offers rich flavor and smooth texture. It requires tempering for a glossy finish and firm snap, making it ideal for desserts like brownies, ganache, and truffles.

- Coating Chocolate: Uses vegetable fats (like palm kernel oil) instead of cocoa butter, making it easier to melt and set without tempering. It's perfect for dipping, molding, and decorative tasks but has a simpler flavor and a waxy texture.

Quick Comparison

| Feature | Baking Chocolate | Coating Chocolate |

|---|---|---|

| Fat Source | Cocoa butter | Vegetable fats (e.g., palm oil) |

| Tempering Needed | Yes | No |

| Texture | Smooth, firm snap | Slightly waxy, softer snap |

| Melting Point | ~95°F | 95°F–99°F |

| Best For | Premium desserts, ganache | Dipping, decorations |

Choose baking chocolate for recipes where flavor and texture matter most. Opt for coating chocolate when ease and stability are your priorities.

Baking Chocolate vs Coating Chocolate: Complete Comparison Guide

ALL ABOUT CHOCOLATE - Couverture vs. Baking Chips vs. Compound Coating

sbb-itb-529d1c3

Composition Differences

The ingredients in baking chocolate and coating chocolate play a big role in their melting behavior and flavor. Baking chocolate is made from cocoa mass, cocoa butter, and sugar, with milk powder included for milk and white varieties. The cocoa mass itself contains both cocoa solids and cocoa butter, giving it a rich and complex flavor.

Coating chocolate, on the other hand, uses a different approach. Instead of cocoa butter, it relies on vegetable fats like palm kernel, coconut, or shea oil, and replaces cocoa mass with cocoa powder. As Puratos explains:

"Real chocolate is made using sugar and two ingredients obtained from the cocoa bean (cocoa mass and cocoa butter)... In coating chocolate, the cocoa butter is replaced by vegetable oils and cocoa powder is used instead of cocoa mass"

. This substitution is largely cost-driven, as cocoa butter can be around five times more expensive than palm oil. Additionally, using vegetable fats eliminates the need for tempering.

Baking Chocolate Composition

Baking chocolate comes in several varieties, which are categorized by their cocoa content and sugar levels. Unsweetened baking chocolate, for example, contains 100% cacao with no added sugar. Its intense bitterness and crumbly texture make it unique, and in the U.S., it must have 50% to 58% cocoa butter. Bittersweet chocolate typically has about 70% cacao, while semisweet hovers around 60%, making them interchangeable in most recipes.

For a higher-grade option, couverture chocolate stands out. This premium variety contains 30% to 40% cocoa butter, giving it excellent melting properties and a silky texture. Cocoa butter’s melting point, which is close to body temperature (around 95°F), ensures a smooth, clean finish that melts effortlessly on the tongue.

Coating Chocolate Composition

Coating chocolate is formulated differently, with 35% to 40% fat, usually in the form of hydrogenated palm kernel oil. Its ingredients include cocoa powder, sugar, milk solids, and emulsifiers like lecithin, which improve its flow and ease of use. The type of cocoa powder used can vary - low-fat cocoa powder contains 10–12% cocoa butter, while high-fat versions range from 20–24%.

The vegetable fats in coating chocolate have a higher melting point (95°F to 99°F), making it ideal for use at around 104°F when coating. While this higher melting point enhances its stability at room temperature, it also gives the chocolate a waxy texture, as it doesn’t melt as smoothly in the mouth. Adam Sabon from Bakers Authority explains:

"Compound chocolate lacks the depth of flavor and texture found in couverture. It can feel waxy and greasy due to the vegetable fats, and the chocolate flavor is less pronounced"

. These differences in composition directly affect how baking and coating chocolates behave during melting, tempering, and storage.

Texture and Handling Differences

Melting and Tempering

Baking chocolate relies on precise tempering - a process of carefully heating, cooling, and reheating - to achieve its signature glossy finish and crisp snap. Skip this step, and you might end up with chocolate that's dull, streaky, or covered in white spots (known as bloom).

On the other hand, coating chocolate is made with vegetable fats like palm kernel oil instead of cocoa butter. This difference eliminates the need for tempering. Just melt it, use it, and it sets firmly at room temperature without any extra effort.

Wondering if your baking chocolate is tempered correctly? A simple test: dip a spoon into the melted chocolate. If it hardens and turns shiny within 3 to 5 minutes at room temperature (65°F to 70°F), you're good to go. Now, let's dive into how these melting characteristics impact storage and stability.

Storage and Stability

Baking chocolate is quite sensitive to heat and humidity. With a melting point around 95°F - close to body temperature - it’s prone to bloom if exposed to temperature changes or moisture. Bloom occurs when cocoa butter crystals rise to the surface, creating a white, powdery appearance.

Coating chocolate, however, is more forgiving. Thanks to its vegetable fats, which melt at a slightly higher temperature (95°F to 99°F), it resists bloom and heat better. As Josiah Huelle, Senior Chocolate Technician at Puratos, explains:

"A chocolate-coated cookie will melt in a hot, humid climate faster than one that's coated with a compound. It's not a huge difference, but that 5 degrees can make a big impact".

If you're defrosting coated products from the freezer, keep them tightly wrapped in plastic until they’re fully thawed. This prevents condensation from forming, which could otherwise affect the chocolate's surface.

Texture and Handling Comparison Table

| Feature | Baking Chocolate | Coating Chocolate |

|---|---|---|

| Fat Content | 30% to 40% cocoa butter | 35% to 40% vegetable fats |

| Tempering Required | Yes | No |

| Melting Point | ~95°F | 95°F to 99°F |

| Bloom Resistance | Low | High |

| Shelf Stability | Sensitive to heat and humidity | Stable at room temperature |

| Texture When Set | Firm snap, smooth melt | Softer snap, slightly waxy |

When to Use Baking Chocolate

Best Applications for Baking Chocolate

Baking chocolate shines in recipes where chocolate takes center stage, thanks to its high cocoa butter content. This gives it a smoother texture and better meltability than chocolate chips, making it ideal for dishes like brownies, flourless cakes, ganache, soufflés, and chocolate sauces.

Unsweetened baking chocolate (100% cocoa) is especially useful when you want full control over sweetness, which is crucial for desserts like fudge icing or rich brownies. CakeSpy from Craftsy highlights its importance:

"Using this unsweetened chocolate allows chemical reactions to occur in your baking by controlling the amount of sweetener added".

For cookies, chopped baking bars create irresistible pools of melted chocolate, unlike chocolate chips, which are designed to hold their shape due to stabilizers. As Claire Saffitz, Senior Associate Editor at Bon Appétit, advises:

"I wouldn't bake with an $11 artisanal bar... it should be delicious enough on its own to eat as a snack".

In short, baking bars are perfect when chocolate is the main attraction, but save your pricey artisanal bars for snacking.

Working with Baking Chocolate

To melt baking chocolate, use a double boiler or microwave it in 30-second bursts at 50% power. Keep all tools completely dry - just a drop of water can cause the chocolate to seize and turn gritty.

For tempering, try the seeding method: melt most of the chocolate and then stir in about 25% unmelted chocolate to encourage stable crystal formation. To check if it’s properly tempered, dip a spoon and see if the chocolate hardens with a shiny finish within 3–5 minutes at room temperature (65°F–70°F). If working with large blocks, shave pieces off with a serrated knife for even melting.

When to Use Coating Chocolate

Coating chocolate stands out for its stable texture and quick setting time, making it a go-to choice for decorative and practical applications.

Best Applications for Coating Chocolate

Coating chocolate works wonders for quick, straightforward tasks like dipping treats - think strawberries, pretzels, Oreos, marshmallows, or even bacon. A thin layer sets in just 1–5 minutes at room temperature, while thicker molds might take closer to an hour.

Its fast setting time also makes it ideal for intricate designs like chocolate curls, decorative flowers, and piping done with parchment cones. It's a favorite for creating hot chocolate bombs, drip cakes, mirror glazes, and cakesicles. Unlike traditional chocolate, coating chocolate is more stable in warm conditions. Thanks to its vegetable fat base (instead of cocoa butter), it’s less likely to melt during handling or shipping.

When adding color, stick to oil-based candy colors - water-based dyes can cause the chocolate to seize. To speed up the setting process, refrigerate your dipped items, but avoid freezing, as this can leave a dull film on the surface. If the coating feels too thick for smooth drizzling, opt for wafers with a "three-drop" fluidity rating to improve consistency.

For the best results, professional-grade products are often worth considering.

Mercken's Chocolate Wafers at Gloria's Cake & Candy Supplies

For glossy, precise coatings, Mercken's Chocolate Wafers are a trusted choice. Known for their reliability for over 30 years, these wafers are a favorite among both home bakers and commercial confectioners. At Gloria's Cake & Candy Supplies in Culver City, you’ll find Mercken's wafers in an array of colors and flavors, perfect for any project.

Need tips? The knowledgeable team at Gloria's Cake & Candy Supplies is ready to help you achieve professional results. For example, melt the wafers in the microwave in 15-second intervals at 50% power, stirring between each session to avoid scorching. Whether you’re crafting cake pops for a party or producing candy on a larger scale, Mercken's wafers provide a glossy finish and firm snap - all without the hassle of tempering.

How to Choose Between Baking and Coating Chocolate

Selection Factors

When deciding between baking and coating chocolate, your recipe's specific needs should guide your choice. Real baking chocolate shines in recipes like truffles, bonbons, ganache, and premium chocolate bars. Its rich flavor and smooth texture - thanks to its ability to melt perfectly at body temperature - make it ideal for high-quality confections, though it does require more skill and attention.

On the other hand, coating chocolate is perfect for projects that require speed and simplicity, such as cake pops, decorative drizzles, or dipping frozen treats. It’s particularly beginner-friendly because it doesn’t need tempering - just melt and use. Josiah Huelle, Senior Chocolate Technician at Puratos, highlights the importance of considering your climate:

"A baker making dipped cookies in Minnesota might make different choices than one in Florida because of the climate. A chocolate-coated cookie will melt in a hot, humid climate faster than one that's coated with a compound."

Using real chocolate demands careful control of temperature to avoid issues like fat bloom or a dull, soft finish. For simpler or quicker projects, coating chocolate eliminates these challenges and can even be easily colored with oil-based candy dyes.

Substitution Guidelines

Swapping one type of chocolate for the other is possible, but it comes with trade-offs. For example, if you want to use real chocolate for coating, tempering is essential. Skipping this step will result in a finish that’s soft and lacks shine.

If coating chocolate isn’t available, you can modify regular chocolate by adding 1 tablespoon of shortening per cup (170 grams) of chocolate chips. This lowers the melting point and improves flow, though the final product won’t harden as firmly as tempered chocolate. Similarly, if you’re substituting eating chocolate for unsweetened baking chocolate, be sure to reduce the sugar in your recipe to maintain balance and avoid excessive sweetness.

These tips can help you adapt recipes while maintaining the qualities that make each type of chocolate special.

Conclusion

Understanding the differences between baking chocolate and coating chocolate helps you choose the right option for your culinary projects. Baking chocolate is prized for its rich cocoa butter content, offering a deep flavor and smooth texture. It's perfect for truffles, ganache, and high-end desserts, though it requires tempering to achieve that glossy finish and satisfying snap.

Coating chocolate, on the other hand, swaps cocoa butter for vegetable fats, making it much easier to work with. It doesn’t need tempering, making it ideal for dipping, molding, and coating. While its flavor is simpler and it can sometimes feel a bit waxy, it sets quickly at room temperature and holds up well in warmer conditions.

When deciding which to use, consider your goals. Baking chocolate shines in recipes where flavor and texture are key, while coating chocolate is a reliable choice for decorative tasks, large-scale production, or beginner-friendly projects. If chocolate is the star of the dish, the effort of tempering baking chocolate is worth it. For quick, stable results, coating chocolate is a practical option.

For premium ingredients and expert guidance, turn to a trusted local source. Since 1972, Gloria's Cake & Candy Supplies has been providing quality products for both gourmet and decorative needs. We proudly offer Mercken's chocolate wafers - a favorite coating chocolate brand for over 30 years. Whether you’re a home baker or run a commercial kitchen, our knowledgeable staff is here to help you find the perfect chocolate for your projects. Stop by for personalized advice, same-day pickup, and everything you need to bring your chocolate creations to life.

FAQs

Can I use coating chocolate instead of baking chocolate in brownies or ganache?

Coating chocolate and baking chocolate serve different purposes, and those differences matter. Coating chocolate, often made with compound chocolate, uses stabilizers and vegetable fats instead of cocoa butter. While it can be melted and incorporated into recipes, it may change the flavor, texture, or gloss of the final product. For example, in ganache, you might notice a different mouthfeel, and in brownies, the taste and texture could be slightly altered.

Why does real baking chocolate need tempering but coating chocolate doesn’t?

Real baking chocolate is packed with cocoa butter, which means it needs tempering to stabilize the crystals. This step is what gives it that glossy look, a firm snap, and a silky-smooth texture. Coating chocolate, however, swaps out cocoa butter for vegetable oils. This tweak makes it more heat-resistant and skips the need for tempering. While it sets easily, the trade-off is a matte finish and a noticeably different texture.

How do I prevent bloom or seizing when melting chocolate?

To avoid issues like bloom or seizing, make sure all your tools and containers are completely dry - any moisture can cause chocolate to seize, turning it grainy and unusable. When melting chocolate, do it slowly and carefully. Use a double boiler over low heat or microwave it in short bursts, stirring frequently to prevent overheating. The key to smooth, glossy chocolate lies in proper tempering and keeping it free from water at all times.